paint removal sandblast - Racingteam Hofmann - tuning and design - BBS motorsport - powder coating

Main menu:

Our paint removal process has been developed using warm chemical baths. For example any oils, dirt, lacquer and paint on aluminium wheels is completely dissolved in the hot chemical solution only leaving the raw metal in its original form without harsh abrasion to the surface. We use this process to prepare most parts for refurbishment to obtain a high quality finish.

Advantages of hot paint removal:

- consistent surface

- excellent results even in hard reach places

- low abrasion

questions and orders to:

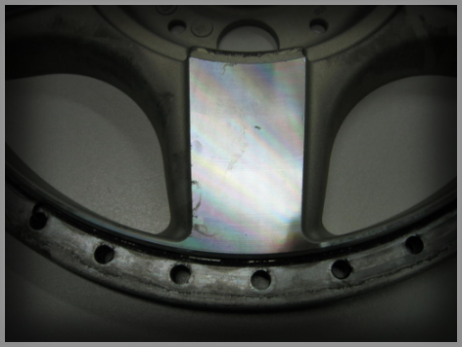

before treatment

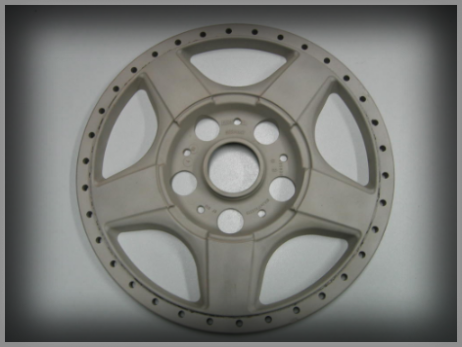

sandblasting

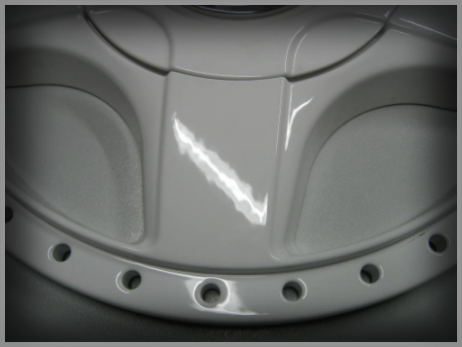

before treatment

We use fine sand granules to carefully clean almost every metallic component from rust, dirt, paint residues or other impurities. Any small imperfections are eliminated. Sand blasting prepares the bare metal surface to ensure the powder coating effectively adheres and provides a hard wearing, long lasting, high quality finish.

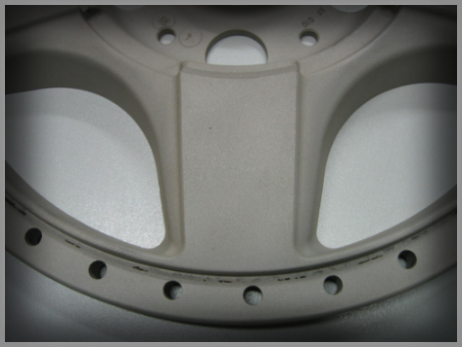

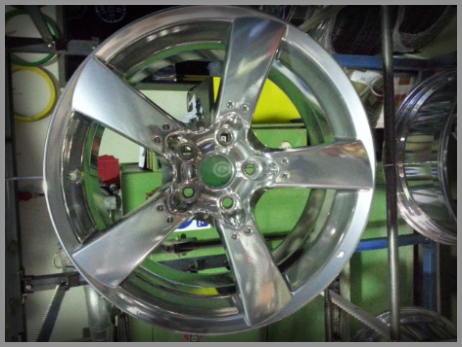

after treatment

after treatment

powder coating

Especially for used or damaged wheels is powder coating one of the best variants, next to high gloss polishing, to leave old rims complete again shine like new. With appropriate preparation of the rim or the components as hot paint removal or over tighten respectively grinding, this small damages can be eliminated.

during the powder coating are fundamentally cleaned, heat resistant parts such as Alloy wheels, brake calipers, axles, etc ... electrostatically charged and and evenly coated with a special color powder coating.

The metal is electro-statically charged and evenly coated with powder paint then baked at and cured at a fixed temperature of approximately 200 ° C to + 220 ° C. To allow the powder paint to cure.

Therefore, only components can be powder coated who withstand these temperatures.

In our company the components are carefully hot decoated, if not already pretreated - this means it is cleaned until to the metal surface so that an optimum result for the powder coating can be obtained. The surface of the component should be gently cleaned of paint or dirt residues, since structural damages in the component by a powder coating can not be corrected and these remains visible at improper treatment.

All standard colors on the RAL color table can be coated.

Pleas ask!

questions and orders to:

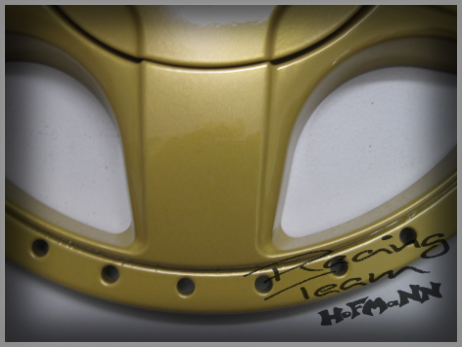

before treatment

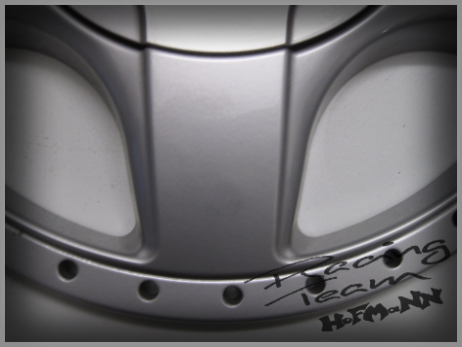

after treatment

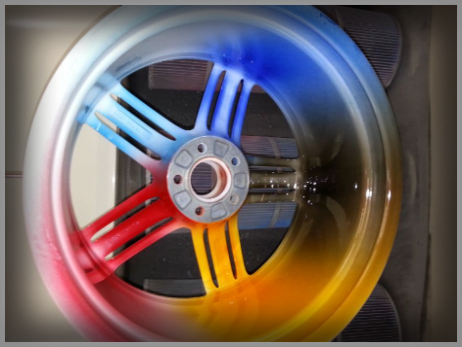

So colored could be shine your wheels!

You decide in which color should shine your new wheels!

Whether with or without additional clear coat - we give your Wheels your desired color tone!

All standard colors on the RAL color table can be coated.

Various glaze colors also available.

First let your wheels high gloss polishing by us and additionally let them shining with one of our glaze colors!

You want to have the look of a high-gloss polished wheels and the same time an easy to clean wheel? which is also more weather resistant?

We have the solution!

- chrome powder coating -

You want to have wheels that no one else has?

Let your wheels according to your wish powder coating!

privacy policy - imprint - conditions - contact - home